Roll Form Tap Drill Chart

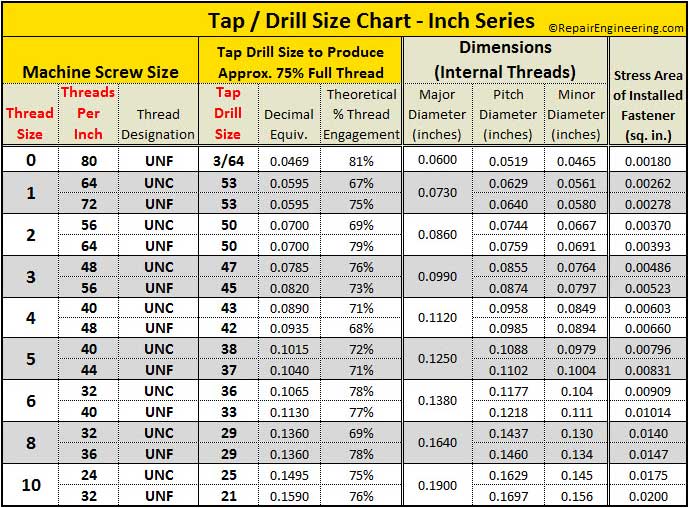

Roll Form Tap Drill Chart - Finding the correct drill size for a spiralock tap may. Web printable chart downloads at the bottom of the page jarflo pipe taps jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Grey cast iron, malleable and spheroidal iron. Thread forming taps can be very effective when used properly. Free, easy returns on millions of items. Web use this chart from kodiak cutting tools for reference with thread forming tap drill sizes. Desired threading size and % about full threading are intake. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest. Web most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. Web achieve precise and consistent results with our range of form taps. Common metric and fractional tap sizes and pitches. Hole sizes for cold form tapping. Cutting rate recommendations for cut taps. Free, easy returns on millions of items. Free shipping on qualified orders. Hole sizes for cold form tapping. Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. A common internal thread drilled out. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a. Cutting rate recommendations for cut taps. Special, super and titanium alloys. Web roll form tap drill size (approx.) m3: Web a common internal thread, drilled so that it results in 50% of full thread will break the external thread, before the internal thread will strip. Web 40 rows tap size cut tap drill roll tap drill minor θ major θ; Free shipping on qualified orders. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest. Web roll form tap drill size (approx.) m3: Cutting rate recommendations for cut taps. A tapping guide for selecting tap drill sizes and proper pitch diameters. Thread forming taps can be very effective when used properly. These charts are supplied as a recommendation only. — (.0068 x % of thread desired) threads per inch 068 x 250 — =.228 dia. Hole sizes for cold form tapping. Cutting rate recommendations for cut taps. Desired threading size and % about full threading are intake. — (.0068 x % of thread desired) threads per inch 068 x 250 — =.228 dia. Web a common internal thread, drilled so that it results in 50% of full thread will break the external thread, before the internal thread will strip. Web tap driil size = basic tap 0.0.. Web printable chart downloads at the bottom of the page jarflo pipe taps jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Hole sizes for cold form tapping. Web achieve precise and consistent results with our range of form taps. Web a rule of thumb is that the right tap drill is. Thread forming taps can be very effective when used properly. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest. Web tap driil size = basic tap 0.0. Web roll form tap drill size (approx.) m3: Special, super and titanium alloys. In general, tap tool life can be increased significantly by using a lower. Web calculations are completed according to roll form tap drill charts which are given in the machinery's handbook. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest. Web printable chart downloads at. Web most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. Cutting rate recommendations for cut taps. Finding the correct drill size for a spiralock tap may. Web achieve precise and consistent results with our range of form taps. These charts are supplied as a recommendation only. — (.0068 x % of thread desired) threads per inch 068 x 250 — =.228 dia. A common internal thread drilled out. Web calculations are completed according to roll form tap drill charts which are given in the machinery's handbook. Free shipping on qualified orders. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest. Web tap driil size = basic tap 0.0. Finding the correct drill size for a spiralock tap may. Desired threading size and % about full threading are intake. Web achieve precise and consistent results with our range of form taps. Special, super and titanium alloys. Web use this chart from kodiak cutting tools for reference with thread forming tap drill sizes. Web high speed machining guide. A tapping guide for selecting tap drill sizes and proper pitch diameters. Ad browse & discover thousands of brands. Forming taps forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. These charts are supplied as a recommendation only. Web a rule of thumb is that the right tap drill is around 85% for coarse threads and 90% for fine threads which feature a higher number of threads per axial distance. Web a common internal thread, drilled so that it results in 50% of full thread will break the external thread, before the internal thread will strip. Thread forming taps can be very effective when used properly. Common metric and fractional tap sizes and pitches.Tap Drill Chart

roll tap drill size chart pdf Britney Champion

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

roll tap drill size chart pdf Britney Champion

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

9+ Sample Tap Drill Charts Sample Templates

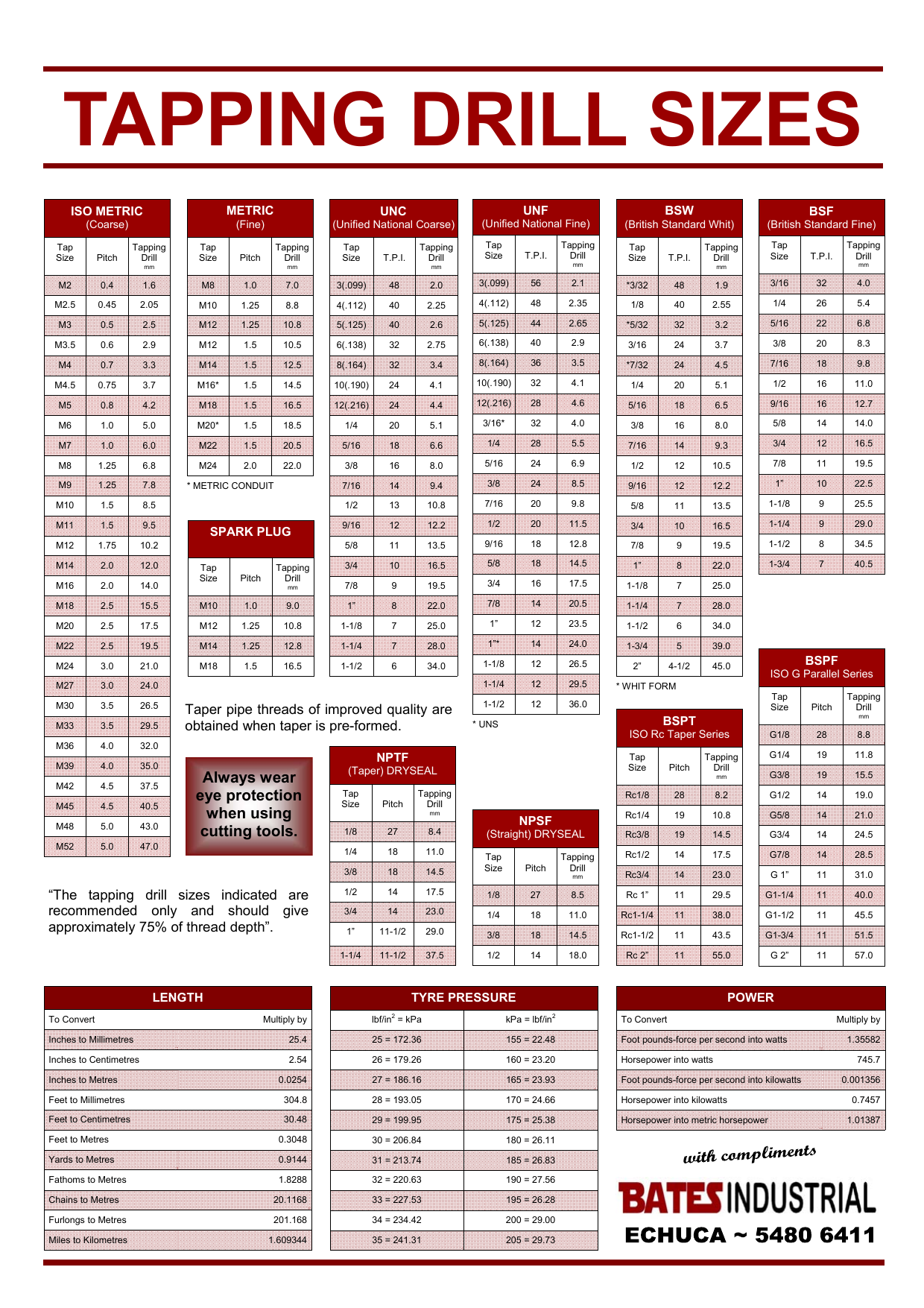

Engineering Supplies Tapping Drill Chart 3

FREE 8+ Sample Tap Drill Chart Templates in PDF

reverse tapping head question

Related Post:

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-02.jpg)

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](https://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-19.jpg)

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-04.jpg?w=320)